- __

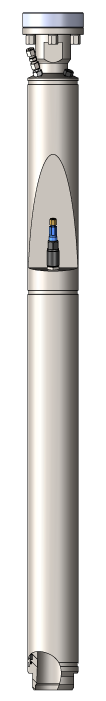

Centriline ESP Power Cables

Delivering reliable power to ESP systems in the harshest downhole environments

Centriline® FLUORO BARRIER™ CEB Cables are designed to operate over a broad temperature range. The FLUORO BARRIER materials are specifically selected to complement the well conditions for each applications. The 300°F (149°C) and the 400°F (204°C) products use a patended high modulus, oil resistant, breathable EPDM insulation with proven electrical properties formulated for harsh conditions. Galvanized steel armor provides an overall protection to the cables.

Centriline® Duralead® CEL cable is designed to operate at temperatures up to 500°F (260°C). The insulations is a specially compounded, oil resistant EPDM rubber with proven electrical properties. Over the insulation, a fatigue and corrosive resistant lead sheath is used that is impervious to chemical and gas migration. The lead sheath barrier prevents decompression and is ideal for wells that have hot and gassy conditions. A bedding tape is used to protect the lead sheath during application of the armor. CEL can be provided with special armors as required by different well conditions.

Centriline® CPN cable is designed for a maximum operating temperature of 280°F (138°C). The insulation is the best grade of polypropylene for downhole applications. Our specially formulated nitrile rubber jacket provides added physical protection, reducing the possibility of damage due to gas, head, and pressure. The CPN design is available in a flat configuration for wells with marginal clearance. Galvanized steel armor provides overall protection to the cable.