- __

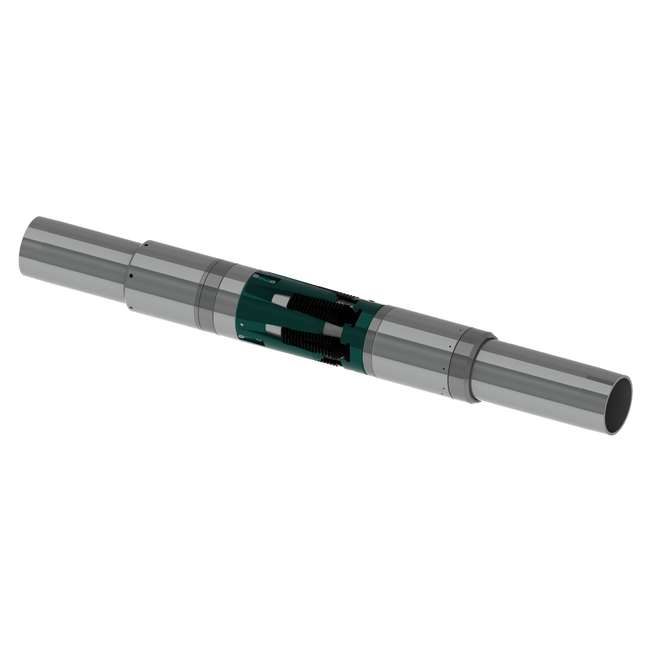

FLEX-LOCK liner hanger system

The FLEX-LOCK V™ liner hanger provides operators with an unmatched level of hanging reliability in today’s most demanding applications through a proprietary slip-seat design, rotational ability, and incredibly robust construction.

The FLEX-LOCK V liner hanger provides operators with an unmatched level of hanging reliability in today's most demanding applications through a proprietary slip-seat design, rotational ability, and incredibly robust construction. Built on the field-proven methods of previous FLEX-LOCK liner hanger generations, the new FLEX-LOCK V liner hanger system has been optimized for extreme downhole conditions such as wellbores containing heavy drilling fluids or fluids with high solids content, as well as applications where liner rotation is required to get the liner to setting depth. A non-welded, slip-seat-style hanger design—which provides greater hanging capacity than basic slip and-cone hanger designs—distributes the liner weight circumferentially and has a larger slip contact area to help minimize collapse loading and deformation of the casing inside diameter. An optimized slip-seat wedge profile and slip-rail design increase tolerance against solids pack-off, enhancing operators' reliability in the heaviest liner hanger applications. Advantages of the FLEX-LOCK V liner hanger include:

- Robust hanging capacity

- Supports the heaviest liner weights with minimal stress concentration on the casing

- Streamlined profile

- Resists packed-off solids and improves reliability

- Premium FLEX-LOCK Control SET system version

- Features a cylinder locking mechanism and is hydraulically balanced

- Prevents hanger presets in high-rate, high-pressure circulation applications or when debris is present

- Rotationally locked (optional)

- Features designed for increased durability

- Enables rotation so liners can be reliably run to setting depth.