- __

- __

CoPilot 2.0/CoPilot UHD

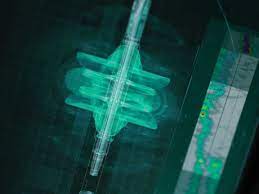

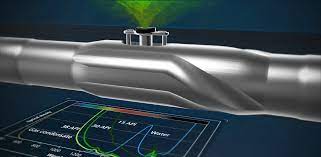

The CoPilot™ drilling performance sub is a short modular sensor sub that can be integrated into a Baker Hughes bottom hole assembly (BHA). As the most advanced, versatile downhole data acquisition and processing system in the industry, it offers real-time downhole pressure and dynamics information including static tool data, weight and torque on bit, bending moment, bending orientation, annular and bore pressure. Placement of the sub can be optimized for client-specific applications, yielding important insights into the effects of downhole mechanics. This technical solution is complemented with real-time engineering expertise to optimize overall drilling efficiency, reduce nonproductive time, and enhance the design of drilling systems and processes over the course of a drilling campaign.

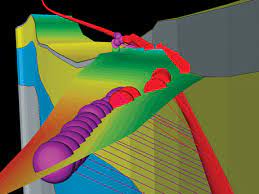

Meet critical production targets on time and accelerate learning based on the data. Use the data for early detection and resolution of drilling problems, such as drillpipe fatigue, twist offs, and high local doglegs. You can apply this knowledge to improve future projects.

The modular CoPilot sub can be positioned anywhere in the bottom hole assembly (BHA), depending on drilling application or logging requirements. These data improve wellbore quality through less wear on all BHA and string components. This also offers reduced torque and drag losses, higher lateral reach, improved log quality, and a higher success rate in casing/completion operations.

Our CoPilot service delivers a comprehensive digital drilling record for detailed post-well analysis. This facilitates the development of best practices. With a clearer picture, bit and drilling system selection is improved.

Typical service applications include high-end deepwater and extended-reach drilling projects and challenging interbedded or complex well formations. This service also enhances drilling performance in existing fields with minimized NPT. There is also a minimized impact when introducing new technology into the drilling process.